A new research project, led by Tom Ross, Professor in Food Microbiology at the Tasmanian Institute of Agriculture (TIA), is being praised for its potential to reduce food waste and increase food safety and security.

Better Production, Better Nutrition, a Better Environment, and a Better Life are highlighted in this year’s World Food Day (October 16) under the umbrella theme of “Leave no one behind”, and co-owner of project partner Mantiss Pty Ltd, Grant Swanepoel hopes to address those concerns through the project.

“One of the biggest issues you have in Australia is consistency between published and actual shelf-life,” Grant Swanepoel said.

“That results in food spoilage and waste, and the food miles associated with that. We believe the product that we are validating here is going to bring security to consistency of published shelf-life.

“If we improve shelf life, we give the consumer and retail customers a better experience that also ultimately reduces food waste. That is a fantastic outcome.”

Strengthening global connections

It is hoped the project, which will launch in January 2023, will “open the door” to several preservation methods for processed meats, improve food safety in manufacturing, shipping, and storage while strengthening global ties.

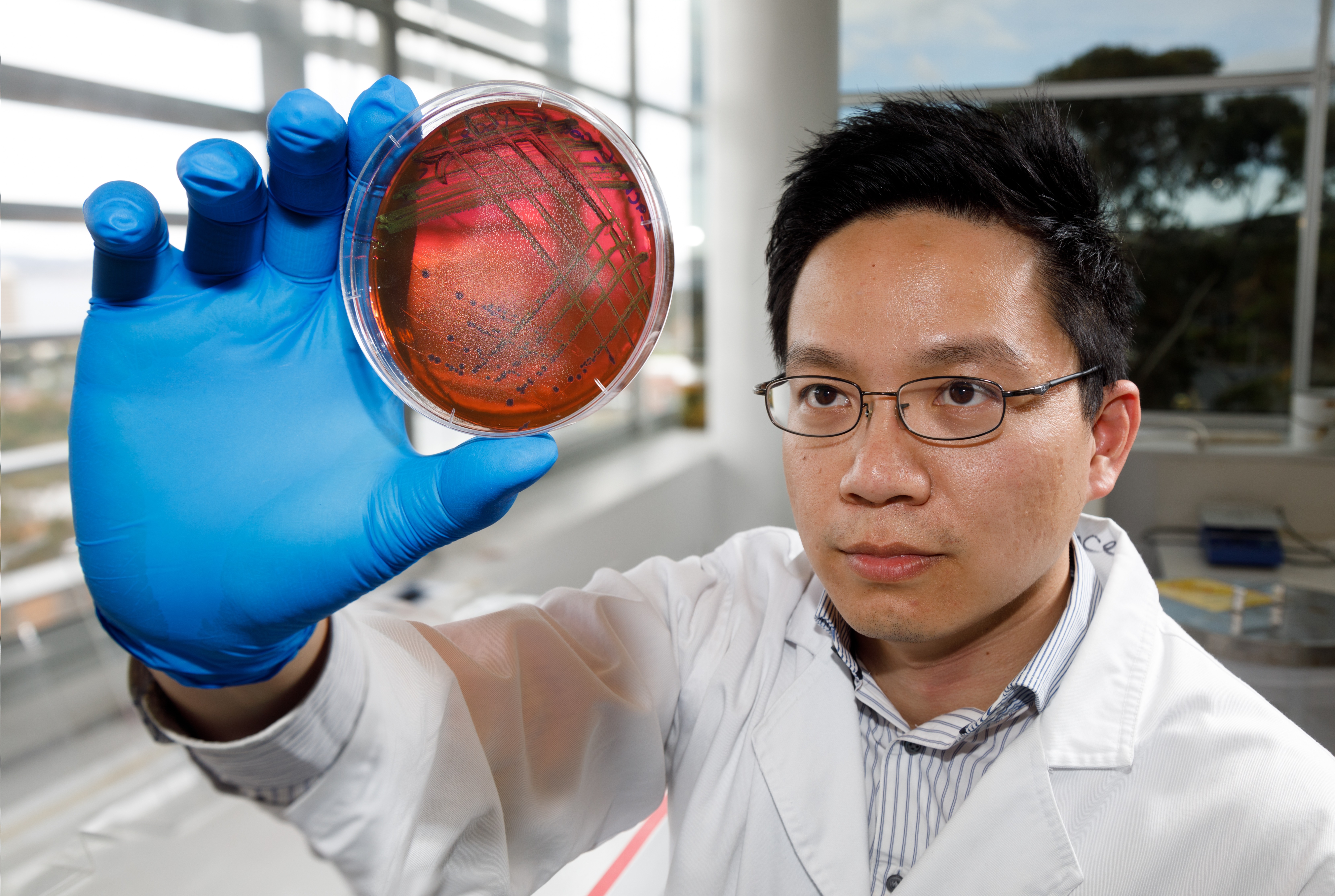

Professor Ross, the project’s Chief Investigator, helped secure the AusIndustry Global Innovation grant for the “Development of complementary preservatives for Australian meat products” in collaboration with two Australian companies, Mantiss Pty Ltd and George Weston Foods and a Spanish company, Chemital. TIA researchers Dr Lyndal Mellefont and Dr Chawalit ‘Jay’ Kocharunchitt will also work on the project.

“Having newer preservation methods will open the door for developing newer, healthier, and more convenient products that, nonetheless, give the same enjoyment that are safe, and have more dependable shelf life,” Dr Ross said.

“The project aims to assess the efficacy and reliability of natural products intended as additives to extend the shelf life and improve the safety of foods. Longer shelf life also increases the opportunity to reach more distant export markets and can reduce food waste.”

The collaborative project will see a family of preservatives evaluated and modified for Australian conditions to provide the local processed meat industry with substantial improvements in food safety and cold chain resilience, for both domestic and export purposes.

“Processed meats (‘smallgoods’) generally have long shelf lives under refrigeration because they are made by traditional methods involving addition of salt, fermentation, or cooking and, in the modern world, using vacuum or modified atmosphere packaging (MAP) as is now commonly used,” Professor Ross said.

This work will focus on Australian smallgoods and a parallel grant has been submitted in Spain, by the Spanish industry partner, Chemital.

The project will be led and co-funded by Mantiss Pty Ltd, the Australian agent for the Chemital products that will be assessed.

“We are responsible for the outcomes and its application,” Grant Swanepoel said.

“When we were talking to people in the industry about this technology there was a view that we need to localise it and it was also referenced to research that had been done overseas, but not locally.”

Mantiss approached Tom Ross and his team at TIA and together began the process of applying for an AusIndustry Global Innovation Grant.

“It is very humbling to work with Tom, we feel we are in very capable hands, so do the Chemital people; they are working with an Australian team of researchers for the first time.”

Many existing preservation systems have a sodium content that has notes that are detectable in the finished product, and when a longer shelf life is desired that dose might increase.

Several products will be assessed in the research to represent the variety and geography across the Australian food sector, from products that go into a pizza business, major supermarket chains, Christmas hams (that are impacted by the specifics of seasonality), shaved ham products, and products going into cafes and retail outlets.

“We could look back at this in 20 years and say a piece of research was done back then to produce ground-breaking technology in food safety for this category and from that moment on we changed direction as an industry,” Mr Swanepoel said.

TIA is a joint venture of the University of Tasmania and the Tasmanian Government.