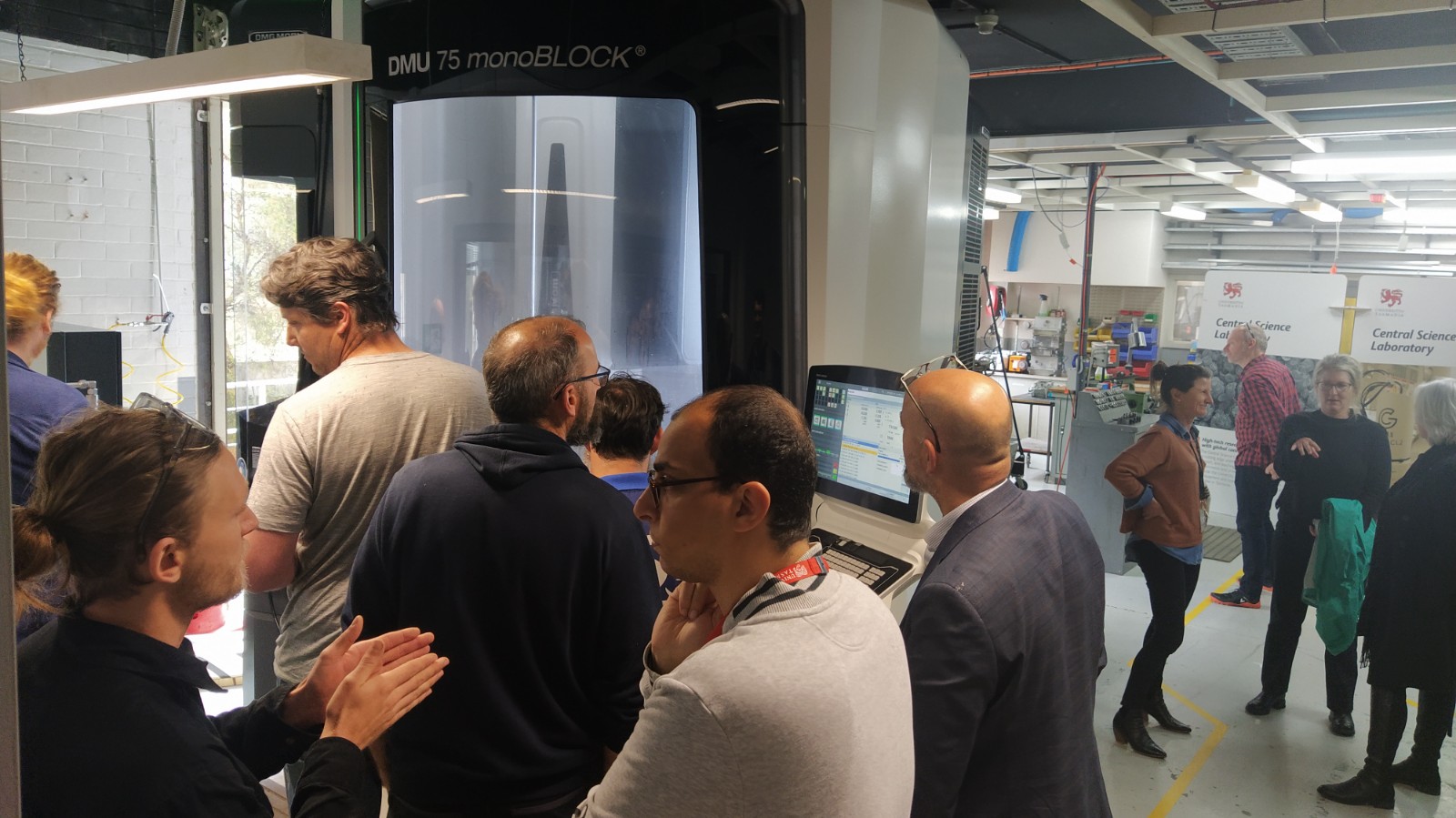

A launch BBQ and “open workshop” on Friday 28th of October saw around 100 leaders, staff, students, and external guests take opportunity to visit the facility, see the new machine in action, and importantly meet with our workshop experts Sean and Phil. It was great to see so many visitors from right across the institution including Chemistry, Earth Sciences, Biological Sciences, IMAS, TIA, Health and Medicine, as well as AAD colleagues. We believe the new machining centre will be a real asset to researchers in the south needing bespoke design, fabrication and repair of specialist parts.

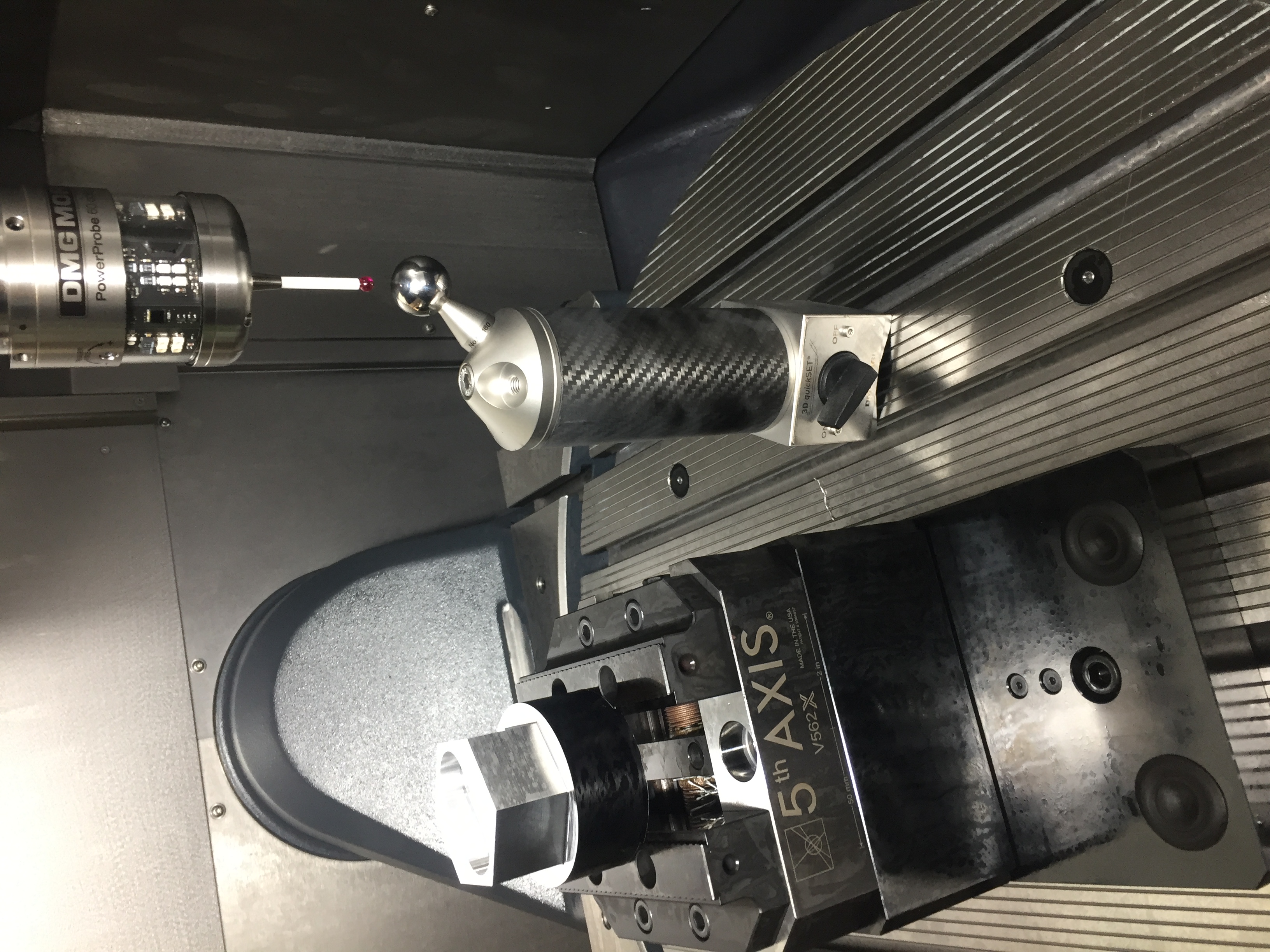

This DMG Mori 5-axis CNC Machining Centre (DMU 75 Monoblock) is capable of extremely precise, detailed, and reproducible custom parts manufacture. It features the ability to make parts out of a wide variety of materials including wood, plastics, and all metals, and boasts a machining accuracy and repeatability to 8 micrometres, even on aeronautical grade metals such as titanium. The multiple rotational axes enable bespoke shapes to be machined in a single set-up, thus minimising time and cost of part production and offering improved reproducibility and efficiency compared to conventional milling. This machining centre can take work pieces up to 600 kg and 500 mm in height and 650 mm in diameter.

Our dedicated Workshop technical staff are available to work directly with clients through the design process which includes computerised 3D modelling to validate part design and fit to other components prior to machining. Furthermore, through the personalised service our staff provide it is even possible to continue to modify the design and part during the machining process. Custom part manufacture is possible for all purposes including research and development applications, and the generation of parts which may no-longer be commercially available.

We welcome your projects and are open to both UTAS and external clients alike.