Start Date |

Jan 30, 2016 12:00 pm |

|---|---|

End Date |

Feb 7, 2016 5:50 pm |

Venue |

Plimsoll Gallery, Hunter Street |

Abstract:

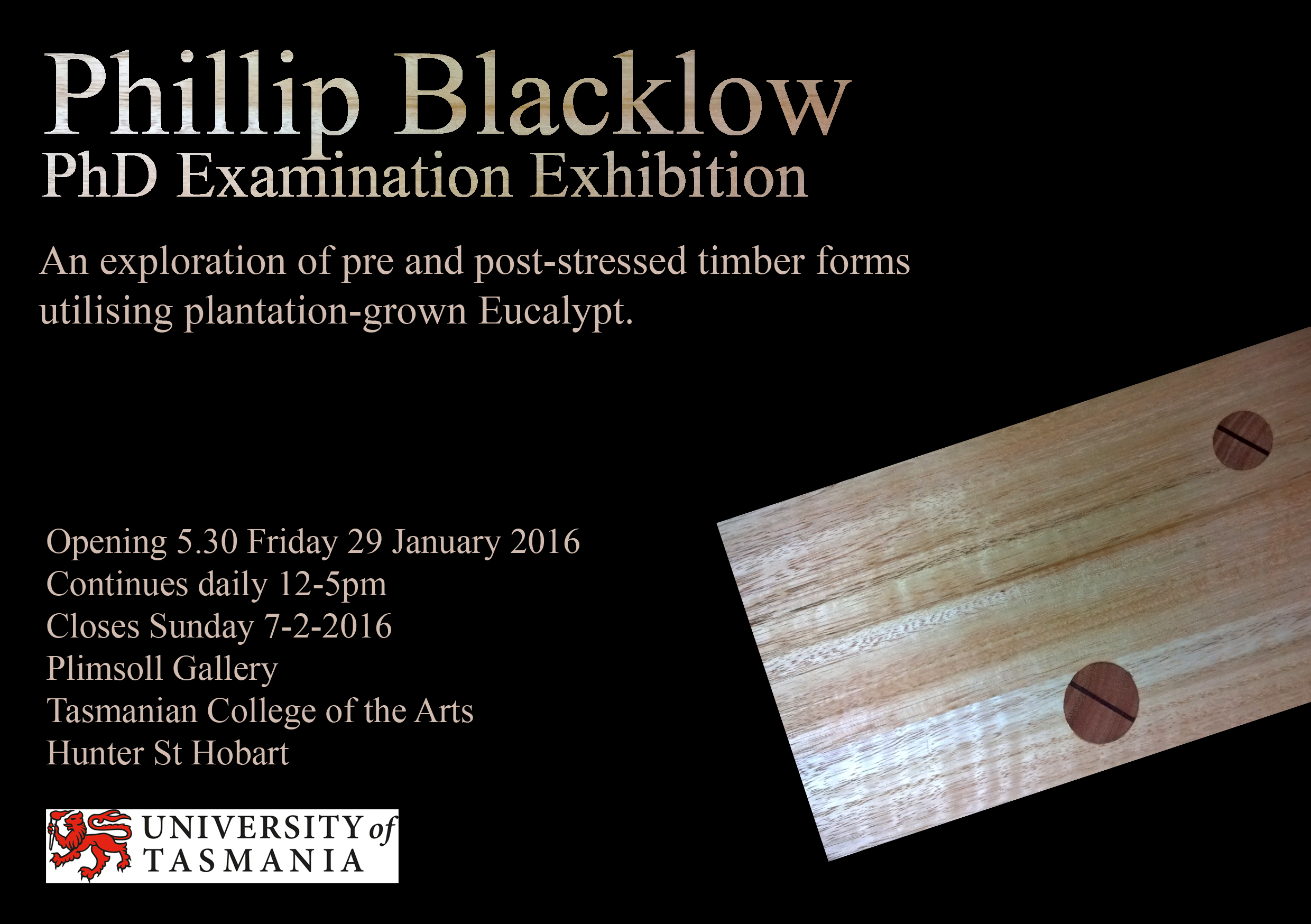

An exploration of pre and post-stressed timber forms utilising plantation-grown eucalypt

This research investigation concerns the behaviour of plantation-grown and natural forest eucalypt timber during secondary processing, from sawn and dried boards through to the production of fine-furniture.

Tasmanian eucalypt plantations comprise only two species, Eucalyptus globulus [E. globulus] and E. nitens. Most Tasmanian plantations have been managed on short rotations to supply the pulpwood market. However a proportion of Tasmanian plantations have been pruned and thinned and are being grown on longer rotations to produce high quality sawlogs. The specific focus of this research is the timber produced from these sawlog plantations.

Preparatory to the testing phase, a review of previous research on growing and primary processing of plantation-grown eucalypt timber was undertaken in order to better understand how it might differ from native forest timber. It was evident that advances in growing, sawing and drying techniques developed in recent decades have been shown to improve primary processing outcomes.

For this study, sawn timber from a commercial sawing and drying trial on 22.5 year-old plantation sawlogs of E. globulus and E. nitens was obtained. Sawn timber from the most widely available native forest species, Eucalyptus obliqua, was also obtained to provide a control for comparison. The same sawmill produced all of the sawn and dried boards used in this investigation. This removed, as far as was possible, differences in primary processing as a confounding factor in the comparisons.

Research was conducted into secondary processing of the three types of timber. Wood is a complex material with a range of variable micro and macro-scale properties that affect processing outcomes, so this called for craft expertise to be applied. Each stage of processing was fully documented to enable evaluation of the suitability of these timbers for high-end, value-added manufacturing. Packs of timber for study were chosen to give representative samples of the sawn timber produced by the mill. Boards from the packs were randomly selected for evaluation so that the conclusions drawn would be representative of the sets of material under study.

This research encompassed a wide range of techniques required for flat panel construction and the production of more advanced steam bent and laminated forms. A number of modifications to existing techniques and innovative processes, particularly around steam bending, were introduced.

Phillip Blacklow 2016

Exhibition opening: Friday 29 January, 5:30pm - 7:30pm

Exhibition dates: Saturday 30 January - Sunday 7 February

Plimsoll Gallery hours: 12 - 5pm daily, closed Tuesdays and public holidays.

Image Credit: Phillip Blacklow, Lights (detail), plantation-grown eucalypt, 2016